Current Inventory

At Classic Investments, we carry a wide range of classic cars in our inventory. Our inventory moves quickly, so please check this page often to find your next classic car investment. For more information about a particular vehicle, click on the pictures below.

1967 AUSTIN HEALEY 3000 MK. III BJ8

The 1967 Austin Healey 3000 MK. III BJ8 is renowned for its classic British roadster styling, boasting a powerful 2.9-liter inline-six engine that delivers an unforgettable driving experience.

1966 MASERATI Mistral Spyder

This example, cherished under 20 years of ownership, merges the power of a meticulously rebuilt 3.7 Litre engine with the prestige of Maserati’s Classiche certification.

1962 MASERATI Vignale Spyder

Crafted with the exquisite design language of the early ’60s, this Maserati Vignale Spyder is more than just a car; it’s a piece of art.

1958 MASERATI 3500 GT

Presented here is a very early example of the first production automobile to come from Maserati, the 3500GT. Since this car is such an early example, it does have a couple of unique design features not found on a majority of 3500GTs.

1961 Lancia Appia Berlina

This fun little car just emerged from a large Lancia collection on the east coast. Remarkably, after being stored untouched for nearly 30 years, this car is still a largely solid and dry example of (arguably) one of the best cars that Lancia ever produced. The interior presents as mostly original and is usable as-is.

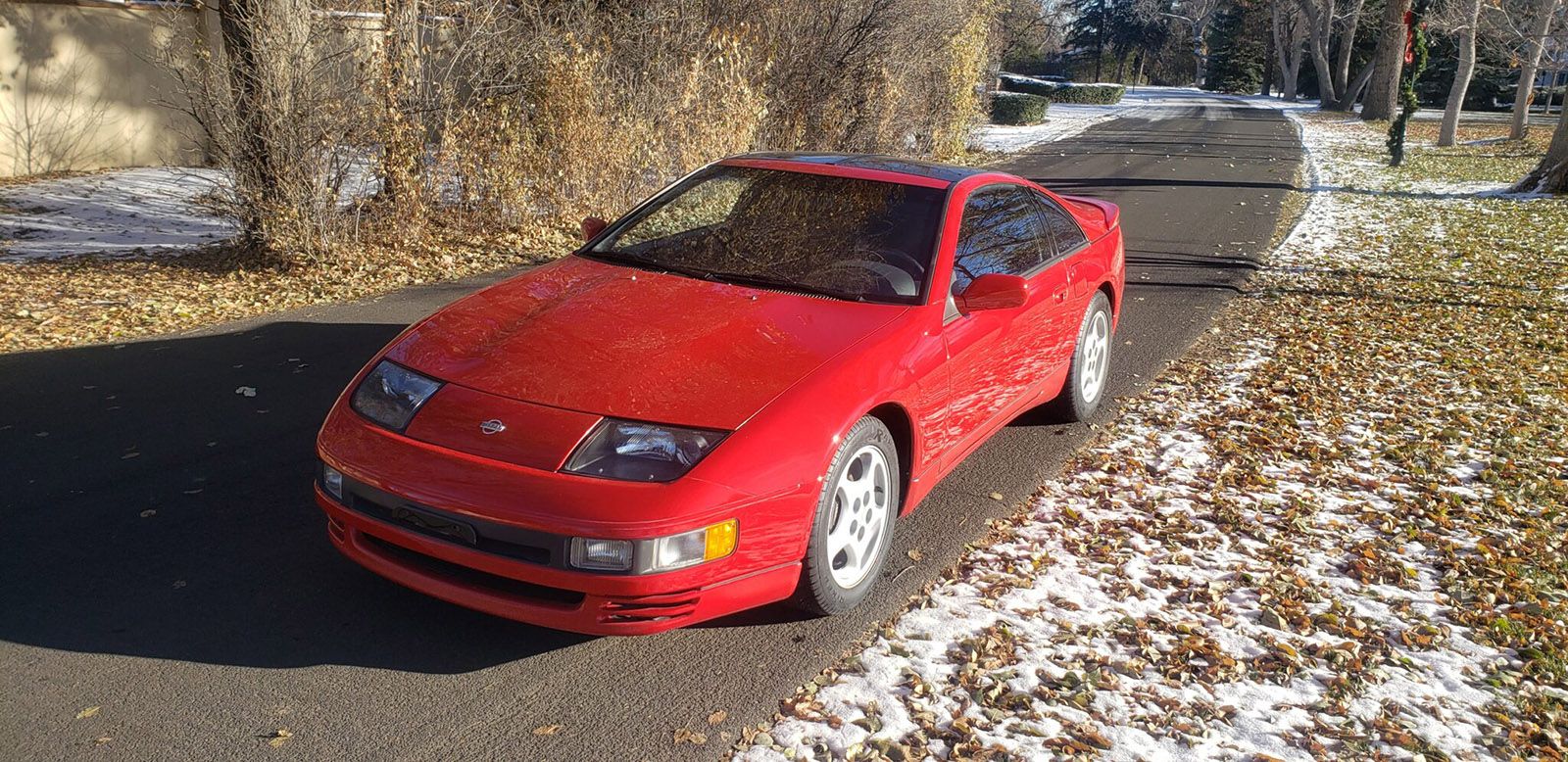

1991 Nissan 300ZX Twin Turbo

A very clean low mileage example of the classic early 90’s JDM icon.

1973 Datsun 240Z

A remarkable early Z car of the first series. Was sitting last several years and has come to life with a major service and a hand detail performed by experts in the field.

Coming Soon

All prices shown are in U.S. Dollars, include dealer prep. and handling fees. Tax, title, registration and transportation costs vary and, are not included in price listed.